rockwell hardness test experiment readings|rockwell hardness testing instructions : trader test. There are three scales on the machine for taking hardness readings. Scale ³A ´ with load . WEBAcademia Smart Fit - A rede de academias Smart Fit tem como propósito democratizar o acesso à prática de atividade física de alto padrão, com planos acessíveis e adesão facilitada. . Av. das Américas, 17701 - .

{plog:ftitle_list}

webSo technically anyone who is producing ballbusting coming out of Canada could be charged. But people do it.. Mistress T is out of Vancouver and Joe and Violet are out of Toronto .

test. There are three scales on the machine for taking hardness readings. Scale ³A ´ with load .The Rockwell test is based on measurement of the depth of penetration with the hardness .The Rockwell hardness test measures hardness by pressing an indenter into the material .Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and .

Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to .The Rockwell hardness of the test piece is calculated by subtracting the second load from the .

The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test .

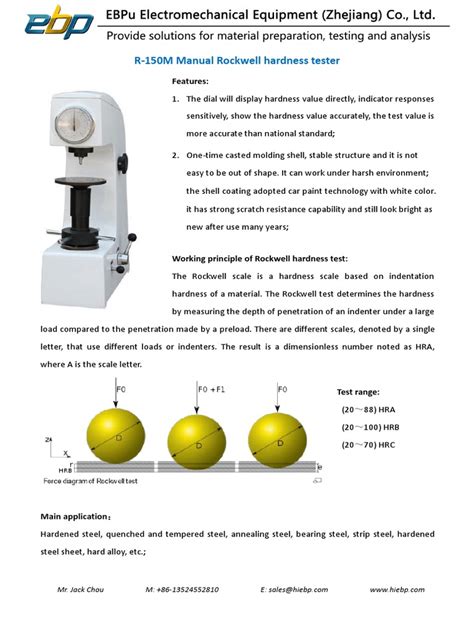

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for . Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. . Care to .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

sl. no. experiment page no. 1. rockwell hardness test 10 2. vickers hardness test 13 3. impact test 16 4. tensile test 21 5. compression test 26 6. shear strength test 29 7. heat treatment 32 8. wear test 35 9. microstructure 39 10. brinell hardness test 43 11. torsion test 46 12. fatigue test 49 13. bending test 53 14. ultrasonic test 56 15.This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).Conduct Tukey's test to make comparisons among the four tips to determine specifically which tips differ in mean hardness readings. c. Analyze the residuals from this experiment.The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.

rockwell hardness testing instructions

rockwell hardness testing guide pdf

The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .

Consider the hardness testing experiment described in Section 4.1. Suppose that the experiment was conducted as described and the following Rockwell C-scale data (coded by subtracting 40 units) obtained: (a) Analyze the data from this experiment. Use alpha = 0.05.

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to measure it. . The dimensionless reading of the Shore A and D readings range between 0 and 100; where 0 represents complete penetration, and 100 .

12 Conclusion This experiment was a complete success as accurate enough results were obtained although results were accurate .It can be seen from readings which are obtained in this experiment using two techniques rockwell and brinell hardness testing that the expected values and the obtained values were very much similar and there were very .The advantages of the Vickers hardness test are that extremely accurate readings can be taken, and just one type of indenter is used for all types of metals and surface treatments. ROCKWELL HARDNESS TEST The penetrators for the Rockwell hardness tester range from 1/2-inch diameter steel . experiment. The Rockwell B scale is suitable for soft .The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. . Tensile Test Experiment . ASTM E8M Tension Testing of Metallic Materials . Case Study In-depth . Subscribe now to keep reading and get access to the full archive.Problem 5) Consider the hardness testing experiment described in lecture. Suppose that the experiment was conducted as described and the following Rockwell C-scale .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter is measured. In contrast, the indentation size is measured in the Brinell, Vickers and Knoop optical test methods.2. State advantages of hardness test using Brinell Hardness Tester. Brinell Hardness Test gives more accurate results as it covers a larger area of indentation as compared to other hardness testing methods such as Vickers’s Hardness Test. 3. State disadvantages of hardness test using Brinell Hardness Tester. The biggest disadvantage of BHN .

this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrialII. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.Rockwell test methods are defined in the following standards: ASTM E18 Metals, ISO 6508 Metals, and ASTM D785 Plastics. It is recommended that operators have . This can come from many sources, all of which will typically cause low readings for Rockwell hardness. If the anvil is damaged, or per- haps has had an indent put into it, then any .

PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on ResearchGate Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: . For Vickers tests, too-light loads create too-small indentations on a part, which leads to inaccurate hardness readings. On the flip side, too-heavy loads could punch all the way through a .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. . With a direct analog reading, this scale has an advanced design and is easy to operate. PHR-100 Portable Magnetic-type Rockwell .

rockwell hardness testing chart

rockwell hardness tester procedure

16 de ago. de 2023 · Conclusion. Voilà, la signification et les manières de lire le fichier BDMV. Vous voyez, vous pouvez lire le fichier avec les lecteurs que nous avons présentés. Mais si vous souhaitez le lire sur votre lecteur multimédia pratique, vous devez d'abord le convertir en vidéo numérique.

rockwell hardness test experiment readings|rockwell hardness testing instructions